The Allen-Bradley PowerFlex 40 is a compact, adjustable frequency AC drive by Rockwell Automation, designed for efficient and precise motor speed control. Its user manual is available as a PDF.

Overview of the PowerFlex 40 Adjustable Frequency AC Drive

The PowerFlex 40 is a high-performance adjustable frequency AC drive designed by Rockwell Automation to provide precise motor speed control in various industrial applications. Known for its compact and space-saving design, it is part of the Allen-Bradley series, offering flexibility and reliability. The drive supports a wide range of motor control applications, from simple speed adjustments to complex process control. Its user-friendly interface and advanced features make it ideal for industrial automation systems. The PowerFlex 40 manual PDF is a comprehensive guide that covers installation, configuration, and troubleshooting, ensuring optimal performance and safety. Rockwell Automation’s commitment to innovation is evident in this product, which balances efficiency, durability, and ease of use.

Applications and Key Features of the PowerFlex 40

The PowerFlex 40 is versatile, catering to various industrial applications such as conveyors, pumps, fans, and material handling systems. Its key features include adjustable frequency control, compact design, and user-friendly programming. The drive supports multiple motor control methods and offers advanced diagnostics for efficient troubleshooting. Its compatibility with Rockwell Automation’s software tools enhances programmability and integration. The PowerFlex 40 manual PDF details these features, enabling users to maximize the drive’s capabilities. Its robust design ensures reliable operation in diverse environments, making it a preferred choice for industrial automation needs. Rockwell Automation’s focus on innovation and customer satisfaction is reflected in the PowerFlex 40’s design and functionality, ensuring it meets the demands of modern industrial processes effectively.

Understanding the PowerFlex 40 Manual

The PowerFlex 40 manual provides comprehensive guidance, including installation, operation, and troubleshooting. It is available as a PDF on Rockwell Automation’s official website for easy access.

Structure and Content of the PowerFlex 40 User Manual

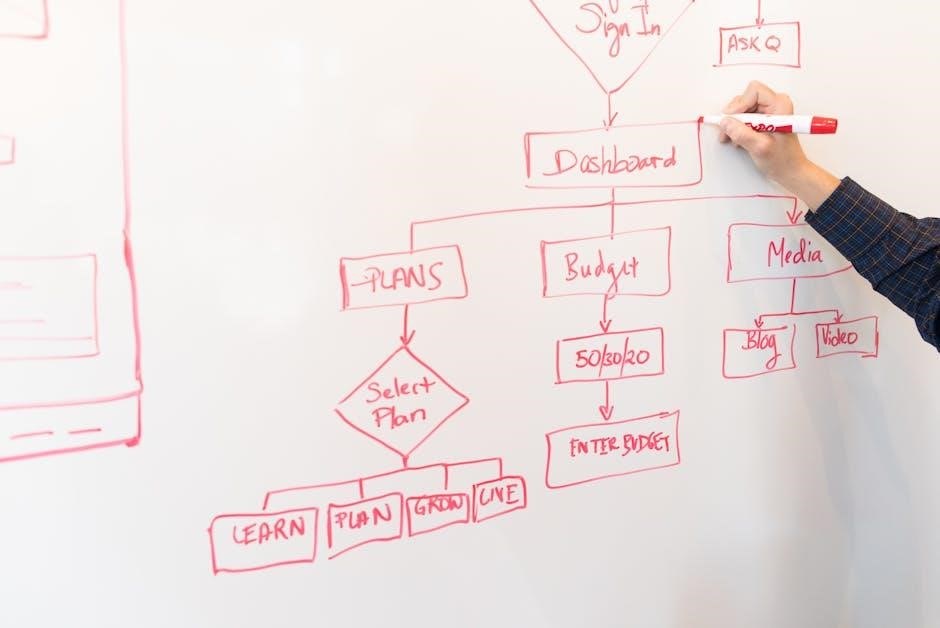

The PowerFlex 40 user manual is structured to guide users through installation, operation, and maintenance. It includes detailed diagrams, troubleshooting tips, and safety precautions. The manual is divided into key sections such as product overview, technical specifications, and step-by-step instructions. Appendices provide additional resources, ensuring comprehensive understanding. Available as a PDF, it is accessible from Rockwell Automation’s official website, making it easy for users to reference whenever needed. The clear organization and detailed content make it an essential resource for optimal use of the PowerFlex 40 drive.

Key Chapters and Sections in the PowerFlex 40 Manual

The PowerFlex 40 manual features essential chapters like installation guidelines, wiring diagrams, and troubleshooting tips. It also includes sections on safety precautions, preventive maintenance, and technical specifications. Detailed appendices provide quick references for common issues. Each chapter is designed to address specific user needs, ensuring comprehensive coverage of the drive’s operation and care. This organized structure helps users navigate effortlessly, making the manual an invaluable tool for both novice and experienced operators. Available online, the PDF format enhances accessibility, allowing users to find information quickly and efficiently. This manual is a crucial resource for anyone working with the PowerFlex 40 drive.

How to Download the PowerFlex 40 Manual PDF

To obtain the PowerFlex 40 manual in PDF format, visit the official Rockwell Automation website. Navigate to the “Literature” or “Support” section. Search for “PowerFlex 40 Manual” or use the publication number 22B-UM001. Select the appropriate document from the search results and follow the prompts to download the PDF. Ensure you have the latest version for accurate information. Additional resources, such as quick start guides, may also be available for download. Always verify the source to ensure authenticity and safety. This manual provides essential details for installation, operation, and maintenance of the PowerFlex 40 drive, making it a vital resource for users. By following these steps, you can easily access the manual and stay informed about your device’s specifications and requirements.

Installation and Setup Guidelines

Refer to the PowerFlex 40 manual for detailed installation steps. Ensure proper wiring and grounding as outlined in the guide. Visit Rockwell Automation’s website for resources.

Pre-Installation Checks and Requirements

Before installing the PowerFlex 40, ensure the site meets all safety and environmental requirements. Disconnect power sources and verify voltage levels match the drive’s specifications. Proper grounding is essential to prevent electrical hazards. Ensure the installation area is clean, dry, and within the recommended temperature and humidity range. Refer to the manual for specific guidelines on handling high-voltage components. All necessary tools and materials should be readily available. Consult the PowerFlex 40 manual for detailed pre-installation steps to ensure a safe and successful setup. Adhere to Rockwell Automation’s recommendations for optimal performance and compliance with safety standards.

Step-by-Step Installation Instructions

Mount the PowerFlex 40 on a flat, stable surface using the provided hardware. Secure it firmly to prevent vibrations. Connect the input and output cables according to the wiring diagram in the manual. Ensure all connections are tight and properly insulated. Power up the drive and use the keypad to navigate through the initial setup menu. Set the motor parameters, including voltage, frequency, and current ratings. Conduct a test run at low speed to verify operation. Refer to the manual for troubleshooting common issues during startup; Follow all safety guidelines to avoid electrical hazards. Proper installation ensures optimal performance and longevity of the drive. Always consult the PowerFlex 40 manual for detailed instructions and specific configurations.

Troubleshooting Common Installation Issues

Common issues during PowerFlex 40 installation include overvoltage, wiring errors, and communication faults. Check the input voltage matches the drive’s rating. Verify all connections are secure and correctly wired according to the manual. If the drive does not power on, ensure the enable input is activated. For motor issues, check if the motor parameters are correctly configured. Use the drive’s diagnostic tools to identify error codes and refer to the manual for solutions. Ensure proper grounding to prevent noise interference. If problems persist, consult the troubleshooting section of the PowerFlex 40 manual or contact Rockwell Automation support. Always follow safety guidelines when troubleshooting to avoid electrical hazards.

Safety Precautions and Maintenance

Ensure safe operation by following manual guidelines, handling high voltage carefully, and performing regular maintenance checks to prevent hazards and optimize the PowerFlex 40’s performance.

General Safety Guidelines for Handling the PowerFlex 40

When working with the PowerFlex 40, always follow safety guidelines to prevent accidents. Ensure the drive is de-energized and voltage is zero before handling. Wear personal protective equipment, including insulated gloves and safety glasses. Avoid contact with internal components to prevent electrical shock. Properly ground the system to eliminate static electricity risks. Never operate the drive in wet or humid environments, as this can lead to electrical hazards. Use only approved tools and follow the manual’s instructions for safe handling. Regularly inspect cables and connections for damage. Keep loose clothing and long hair tied back to avoid entanglement. Always refer to the PowerFlex 40 manual for detailed safety procedures to ensure safe operation and maintenance.

Preventive Maintenance Tips for Optimal Performance

Regular maintenance is crucial to ensure the PowerFlex 40 operates efficiently and reliably. Start by inspecting all electrical connections and cables for wear or damage. Clean dust and debris from the drive and its components to prevent overheating. Verify that the system is properly grounded to maintain safety and performance. Check the input and output voltages against the recommended levels in the PowerFlex 40 manual. Replace any worn or faulty components promptly to avoid downtime. Schedule periodic firmware updates to benefit from the latest enhancements. Always follow the manual’s guidelines for testing and calibration. By adhering to these preventive measures, you can extend the lifespan of the drive and ensure optimal functionality in industrial applications.

Important Safety Considerations During Maintenance

Always disconnect the power supply and ensure the system is de-energized before performing maintenance. Use insulated tools and wear appropriate personal protective equipment, including safety glasses and gloves. Verify that the voltage at the drive terminals is zero using a multimeter, as specified in the PowerFlex 40 manual. Follow proper lockout/tagout procedures to prevent accidental start-up. Never bypass safety features or attempt to modify the drive’s internal components without authorization. Ensure all grounding connections are secure to prevent electrical hazards. Be aware of high voltage components and internal capacitors that may retain charge even after power is turned off. Always refer to the manual for specific safety guidelines and procedures to avoid risks during maintenance tasks.